Wholesale dewatering mini mud pump Factory in China

In the mining industry, water management and removal is critical. As a manufacturer, we know that dewatering mining pumps and dewatering mud pumps play an integral role in this process. These two pumps cooperate with each other during mining operations to ensure the dryness and safety of the mine, while also improving mining efficiency.

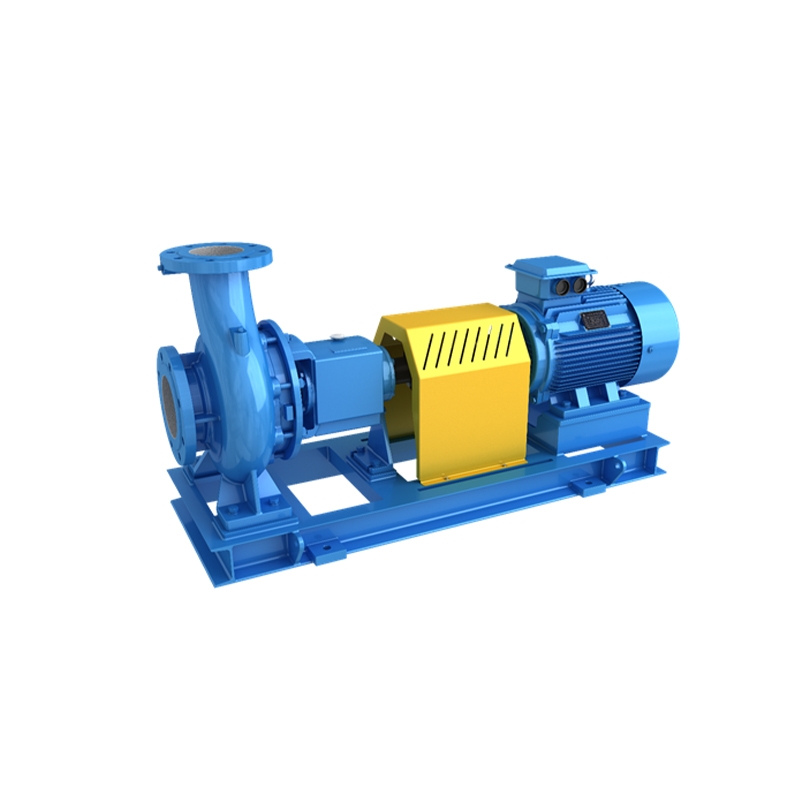

Let's learn about dewatering mining pump. This pump is specifically designed for mining environments and is capable of efficiently removing large volumes of water from mines. A dewatering mining pump is usually installed at the low point of the mine to collect and remove standing water. They have powerful suction and high lift, enabling them to pump water from deep wells to the surface. Such pumps are designed with the harsh conditions of the mining environment in mind, so they are often resistant to corrosion, wear and high temperatures.

Different from the dewatering mining pump, the dewatering mud pump is mainly used to treat mud water containing solid particles. During the mining process, water containing silt and other impurities is often produced. The dewatering mud pump is designed to effectively handle these fluids containing solid particles. They usually have larger flow channels and powerful impellers that can separate sediment and other solid particles from the water and transport them to designated locations.

In mining operations, the coordinated use of dewatering mining pumps and dewatering mud pumps is crucial. When the water in the mine is mainly clean water, the dewatering mining pump can work independently to quickly remove accumulated water. However, when the water in the mine contains a large amount of sediment and other impurities, the dewatering mud pump needs to intervene. The dewatering mining pump first pumps clean water to the surface, while the dewatering mud pump handles the remaining mud water. This division of labor not only improves drainage efficiency, but also reduces equipment wear and tear.

In addition, the combined use of dewatering mining pump and dewatering mud pump also contributes to environmental protection. By effectively treating and removing water from mines, the impact on the surrounding environment can be reduced. The dewatering mud pump can separate sediment and other solid particles from water, preventing these pollutants from entering natural water bodies, and protecting water quality and ecosystems.

When designing the dewatering mining pump and dewatering mud pump, we took into account their ability to work together. We offer both pumps with interchangeable components and a modular design, allowing them to be adapted to specific mining environments and needs. This flexibility allows dewatering mining pumps and dewatering mud pumps to be easily integrated into existing mining systems without the need for extensive modifications.

We also provide advanced control systems for dewatering mining pumps and dewatering mud pumps. These systems can monitor the working status of the pump in real time, including parameters such as flow, pressure and temperature. Through this data, operators can adjust the working status of the pumps in time to ensure that they operate at their better. In addition, control systems can predict and diagnose potential problems, reducing downtime and repair costs.

In the mining industry, safety is always a top priority. Both dewatering mining pumps and dewatering mud pumps are designed to meet strict safety standards. They feature overload protection, short-circuit protection and leak detection to ensure safe operation in any situation.

In summary, dewatering mining pumps and dewatering mud pumps play a vital role in the mining industry. They not only improve mining efficiency, but also contribute to environmental protection and safe production. As a manufacturer, we are committed to providing high quality pump equipment and solutions to meet the needs of the mining industry.

English

English русский

русский عربى

عربى